Choosing the Best Dental 3D Printer Technology: SLA, DLP, or LCD?

The world of dental technology is evolving rapidly, with 3D printing now a key part of modern dental practices. From dental models to implants, dental 3D printers are revolutionizing patient care. Among the technologies available, SLA, DLP, and LCD are the most commonly used systems in the dental field. However, how do they differ? And which one is best for dental applications?

In this article, we will provide a comprehensive comparison of SLA, DLP, and LCD technologies, discussing their advantages and limitations. We will also cover key factors to help dental professionals choose the right technology for their specific needs.

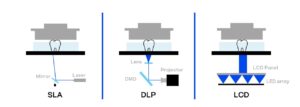

Differences between SLA, DLP, and LCD technologies in Dental 3D Printers

SLA, DLP, and LCD are the most widely used 3D printing technologies in dentistry. All three use photosensitive resins, meaning that each layer is cured by light. This process turns liquid resin into solid layers, eventually building up a complete model. While these technologies seem similar, they differ significantly, especially in terms of the light source.

Main resin 3D printing technologies in dentistry.

Stereolithography (SLA)

SLA was the first 3D printing technology developed in the 1980s. Unlike DLP and LCD, it uses a laser as its light source. The laser beam selectively cures the resin layer by layer as it moves across the resin tank. Although it’s the most precise method, it is also the slowest, making it more suited for detailed dental applications.

Digital Light Processing (DLP)

Image by ViewSonic Library: Digital Micromirror Device (DMD)

Liquid Crystal Display (LCD)

LCD technology is similar to DLP in that both cure entire layers of resin at once. However, the key difference lies in the light source. LCD, also known as MSLA (Masked Stereolithography Apparatus), utilizes an array of UV-emitting LEDs placed beneath an LCD screen, similar to those found in smartphones or tablets. The screen selectively blocks light, allowing it to pass only in areas where curing is needed. This setup not only simplifies the printing process but also reduces maintenance costs by eliminating moving parts.

In addition, since LCD printers project the image directly onto the resin, the model size is limited only by the working area rather than by the projector’s constraints. Despite this advantage, one drawback of LCD screens is their ability to absorb up to 90% of the UV radiation from the LEDs, which makes them slower than DLP printers. For example, while a DLP printer can typically cure a layer of resin in under a second, LCD printers often take over six seconds to complete the same task.

Key Factors Affecting the Performance of Dental 3D Printers

When choosing a dental 3D printer, there are four key factors to consider: resolution, accuracy, precision, and, to a lesser extent, speed. Additionally, for a 3D printer to work optimally, it must be paired with a good CAD design, high-quality resins, and proper post-processing.

Speed

DLP printers are the fastest, with speeds ranging from 30 to 60 mm per hour. However, accuracy and precision decrease when printing models larger than 200 x 120 mm. SLA is much slower, while LCD is somewhere in between.

Accuracy and Precision

In 3D printing, accuracy refers to how closely the printer can replicate the CAD design, while precision means to the repeatability of results. Over time, manufacturers have significantly improved these factors, but some technologies degrade faster. While dental LCD printers are calibrated for high accuracy and precision, their screens wear out more quickly than the optical systems in DLP and SLA.

XY Resolution

In LCD printers, pixel size determines XY resolution (here you can find a more detailed look). In DLP printers, it’s determined by the size of the micromirrors, while in SLA, the laser spot size is key. Resolution mainly affects surface smoothness. High-end SLA printers produce silky-smooth models, while LCD printers rank second.

Material Compatibility

The choice of resin impacts print quality significantly. LCD and DLP printers use highly reactive resins that cure quickly under light and can be used interchangeably. In contrast, SLA requires specially formulated resins to withstand the laser beam.

How to Choose the Right Dental 3D Printers for Your Practice?

When choosing a 3D printer for dental applications, factors such as speed, resolution, and compatibility with different materials should be considered. Additionally, the type of planned applications (models, crowns, bridges, dentures), available capital, and experience should be taken into account. DLP and SLA printers offer high precision but are more expensive to purchase. While LCD printers are more economical, though they require more frequent screen replacements and, in most cases, knowledge of their operation.

Przemysław Grabowski

Challenges of 3D printing in low-temperature environments

When winter does not let up and temperatures drop not only outdoors, problems with 3D [...]

Kacper Włodarek

Dental 3D Printing: Accuracy vs. Resolution

When it comes to 3D printing applications in dentistry, accuracy is everything. It ensures that [...]

Kacper Włodarek

Choosing the Best Dental 3D Printer Technology: SLA, DLP, or LCD?

The world of dental technology is evolving rapidly, with 3D printing now a key part [...]